Factory welded wire mesh

Welded wire mesh is one popular materials in concrete, construction and industry. It is made of low carbon steel wire, PVC coated wire and stainless steel wire, after welding or before welding and surface zinc treating .The welded wire mesh are the most excellent anti-corrosion resistance among all the steel wire mesh products, it is also the most versatile wire mesh due to its wide application in different fieldsWelded wire mesh can come as coils /rolls or flat panels and sheets. It can be constructed from low carbon and stainless steel.

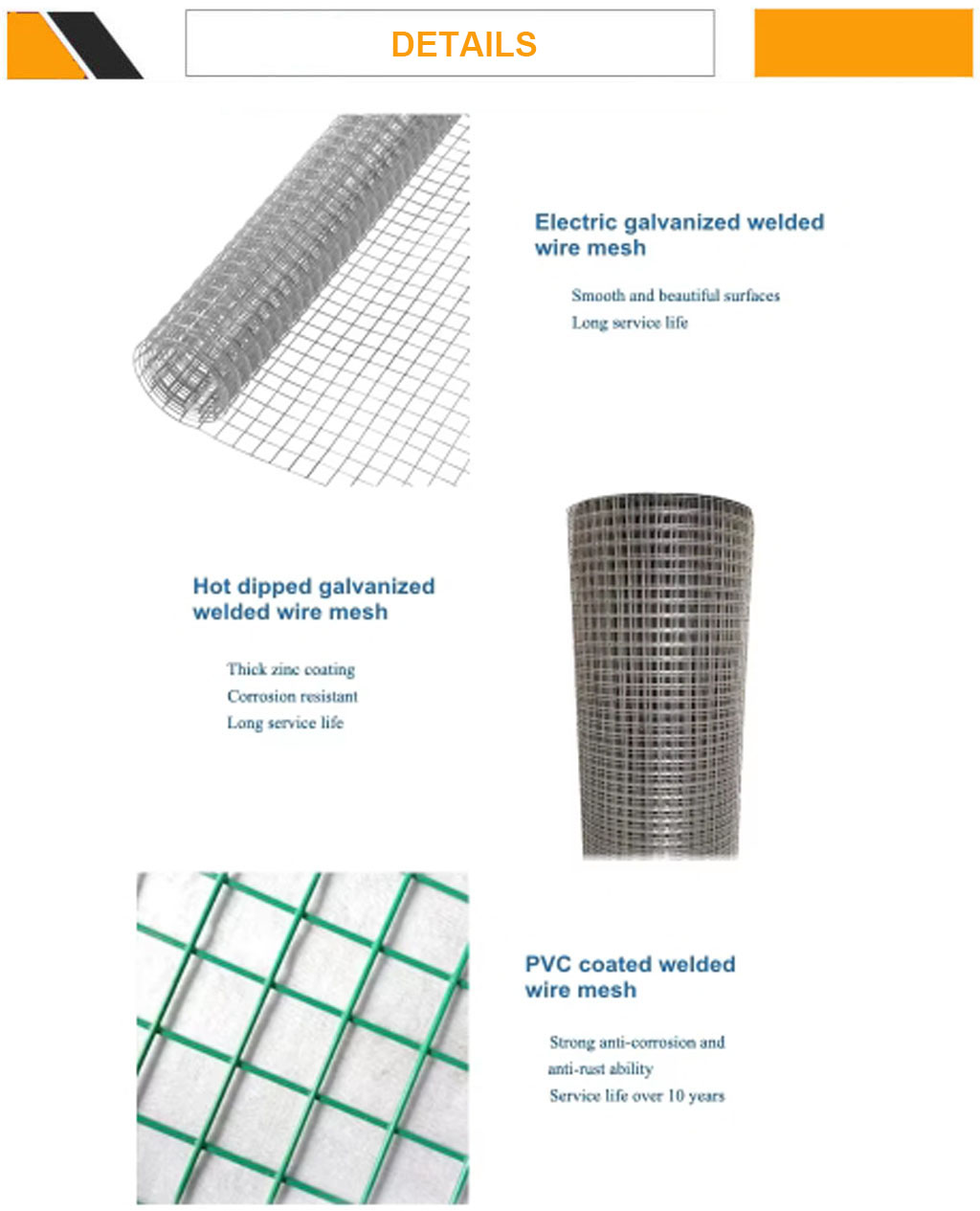

Surface treatment can be electro galvanized an hot dipped galvanized, also can be PVC coated or Powder coating.

Welded wire mesh is quick and simple to install and is not easily displaced by workers laying concrete. The ease of use can reduce completion time and help projects remain on budget. Faster construction time also minimizes the exposure of building components to the elements, resulting in higher-quality work. Classification:

1) Hot Dipped Galvanized before welded

2) Hot Dipped Galvanized after welded

3) Electro Galvanized before welded

4) Electro Galvanized after welded

5) PVC Coated welded wire mesh

6) Stainless Steel welded wire mesh

Surface treatment can be electro galvanized an hot dipped galvanized, also can be PVC coated or Powder coating.

Welded wire mesh is quick and simple to install and is not easily displaced by workers laying concrete. The ease of use can reduce completion time and help projects remain on budget. Faster construction time also minimizes the exposure of building components to the elements, resulting in higher-quality work. Classification:

1) Hot Dipped Galvanized before welded

2) Hot Dipped Galvanized after welded

3) Electro Galvanized before welded

4) Electro Galvanized after welded

5) PVC Coated welded wire mesh

6) Stainless Steel welded wire mesh

| Opening | Wire diameter<BWG> | |

| In inch | I n metric unit(mm) | |

| 1/4”x1/4” | 6.4mmx6.4mm | 22,23,24 |

| 3/8”x3/8” | 10.6mmx10.6mm | 19,20,21,22 |

| 1/2”x1/2” | 12.7mmx12.7mm | 16,17,18,19,20,21,22,23 |

| 5/8”x5/8” | 16mmx16mm | 18,19,20,21 |

| 3/4”x3/4” | 19.1mmx19.1mm | 16,17,18,19,20,21 |

| 1”x1/2” | 25.4mmx12.7mm | 16,17,18,19,20,21 |

| 1-1/2”x1-1/2” | 38mmx38mm | 14,15,16,17,18,19 |

| 1”x2” | 25.4mmx50.8mm | 14,15,16 |

| 2”x2” | 50.8mmx50.8mm | 12,13,14,15,16 |

Send your message to us:

Write your message here and send it to us