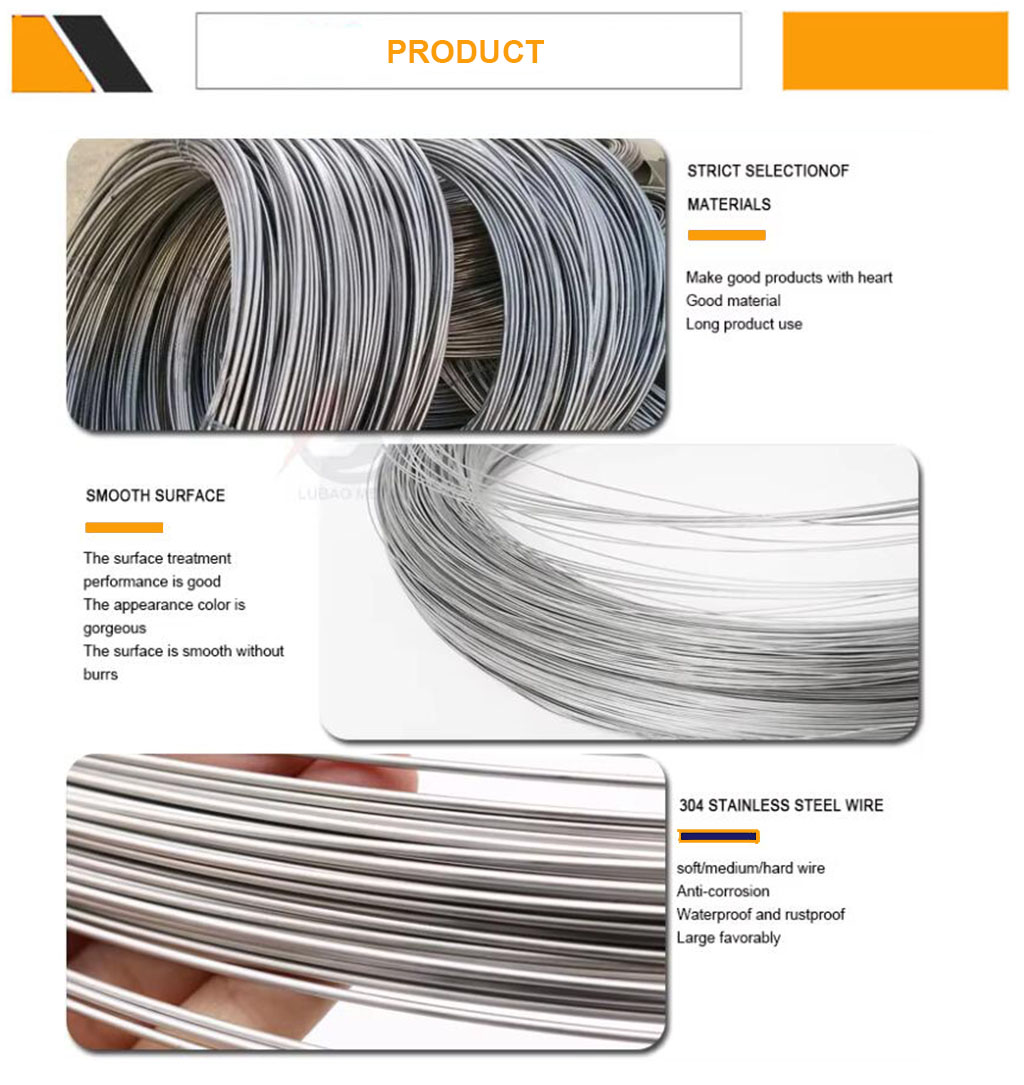

Electric Galvanized Wire Coil Tie Wire small spool wire

* High strength, high bearing capacity. * Corrosion resistance, rust resistance.

* High tensile strength, high elongation.

* Good softness and flexibility, can be bent to various shapes.

* Electrical conductivity.

* It is convenient to use.

* Various types and specifications.

Corrosion resistance

Stainless steel wire contains chromium (Cr) and other alloying elements, chromium can form a layer of dense chromium oxide protective film on the surface of stainless steel wire. This film can prevent oxygen, moisture and other corrosive media from contacting the metal matrix inside the steel wire, so that it has good corrosion resistance. For example, in a humid marine environment or an industrial environment containing chemically corrosive substances, the stainless steel wire can resist the erosion of seawater, acidic or alkaline solutions, and effectively extend the service life.

Strength and toughness

Stainless steel wire has high strength and can withstand certain tension, pressure and bending force. Its strength is derived from its metal crystal structure and alloy composition. At the same time, it also has good toughness, in the impact of external forces, will not easily break. For example, in the production of springs and other parts that need to withstand repeated tension and compression, stainless steel wire can ensure shape recovery at the same time, bear the corresponding force.

High temperature resistance

Many stainless steel wires can be used in higher temperature environments. Different types of stainless steel wire, the degree of high temperature resistance is different. Generally speaking, austenitic stainless steel wire can maintain good performance at higher temperatures (such as 600-800°C), which makes it suitable for some high-temperature working environments, such as supporting the internal structure of a high-temperature furnace or playing a role in the production of parts of a heat exchanger.

Good processing performance

Stainless steel wire can be made into various shapes and sizes through a variety of processing methods. It can be stretched, bent, braided, twisted, etc. For example, when making a metal wire mesh, stainless steel wires can be woven into different mesh shapes and sizes to meet different functional requirements such as filtration and protection.