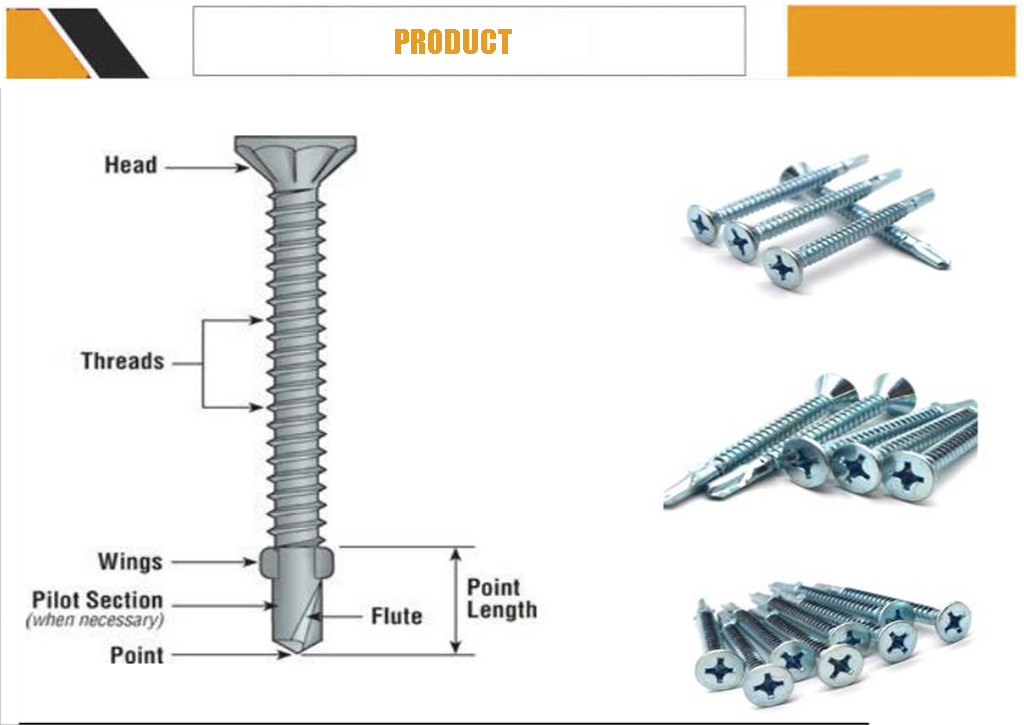

self tapping screw

◈Teks Drill Point

Non walking, cutting edges, pigtail reduction

Engages material faster, drills with less effort, safer installation ◈Load bearing area

Selectively hardened to retain strength and ductility performance similar to a Grade 5 bolt

Resists shear failure due to loading and different expansion coefficients in dissimilar metals ◈Installs faster

Drills and taps faster with fewer stalls

Reduces installation time and money ◈Climaseal ACR

Coating provides long life protection

Fewer replacements

| Size(inch) | Size(mm) | Size(inch) | Size(mm) | Size(inch) | Size(mm) |

| #7×1/2” | M3.9×13 | #8×1/2” | M4.2×13 | #10×1/2” | M4.8×13 |

| #7×5/8” | M3.9×16 | #8×5/8” | M4.2×16 | #10×5/8” | M4.8×16 |

| #7×3/4” | M3.9×19 | #8×3/4” | M4.2×19 | #10×3/4” | M4.8×19 |

| #7×1” | M3.9×25 | #8×1” | M4.2×25 | #10×1” | M4.8×25 |

| #7×1-1/4” | M3.9×32 | #8×1-1/4” | M4.2×32 | #10×1-1/4” | M4.8×32 |

| #7×1-1/2” | M3.9×38 | #8×1-1/2” | M4.2×38 | #10×1-1/2” | M4.8×38 |

| #7×2” | M3.9×50 | #8×2” | M4.2×50 | #10×2” | M4.8×50 |

| #7×2-1/2” | M3.9×63 | #8×2-1/2” | M4.2×63 | #10×2-1/2” | M4.8×63 |

| #7×3” | M3.9×75 | #8×3” | M4.2×75 | #10×3” | M4.8×75 |

| #8×3-1/5” | M4.2×80 | #10×3-1/5” | M4.8×80 | ||

| #8×3-1/2” | M4.2×90 | #10×3-1/2” | M4.8×90 | ||

| #8×4” | M4.2×100 | #10×4” | M4.8×100 |

Send your message to us:

Write your message here and send it to us