High Quality Open Round Head Aluminum Blind Rivets/ Steel Blind Rivets

Blind rivets are tubular and are supplied with a mandrel through the center. The rivet assembly is inserted into a hole drilled through the parts to be joined and a specially designed tool is used to draw the mandrel into the rivet. This expands the blind end of the rivet and then the mandrel snaps off. There are various other manufactures like Avdel Cherry, Gesipa, Marson, Alcoa, and Huck. All of these manufactures make their blind rivets to IFI Standards. Unlike solid rivets, blind rivets can be inserted and fully installed in a joint from only one side of a part or structure, “blind” to the opposite side.

Open-End Aluminum/Steel Blind Rivets

open-type dome head /aluminum body and steel mandrel pop blind rivet

After riveting, the surface of the board is smooth without any protrusions.

Suitable for scenarios such as mechanical equipment, intelligent equipment, new energy vehicles, sheet metal chassis, etc

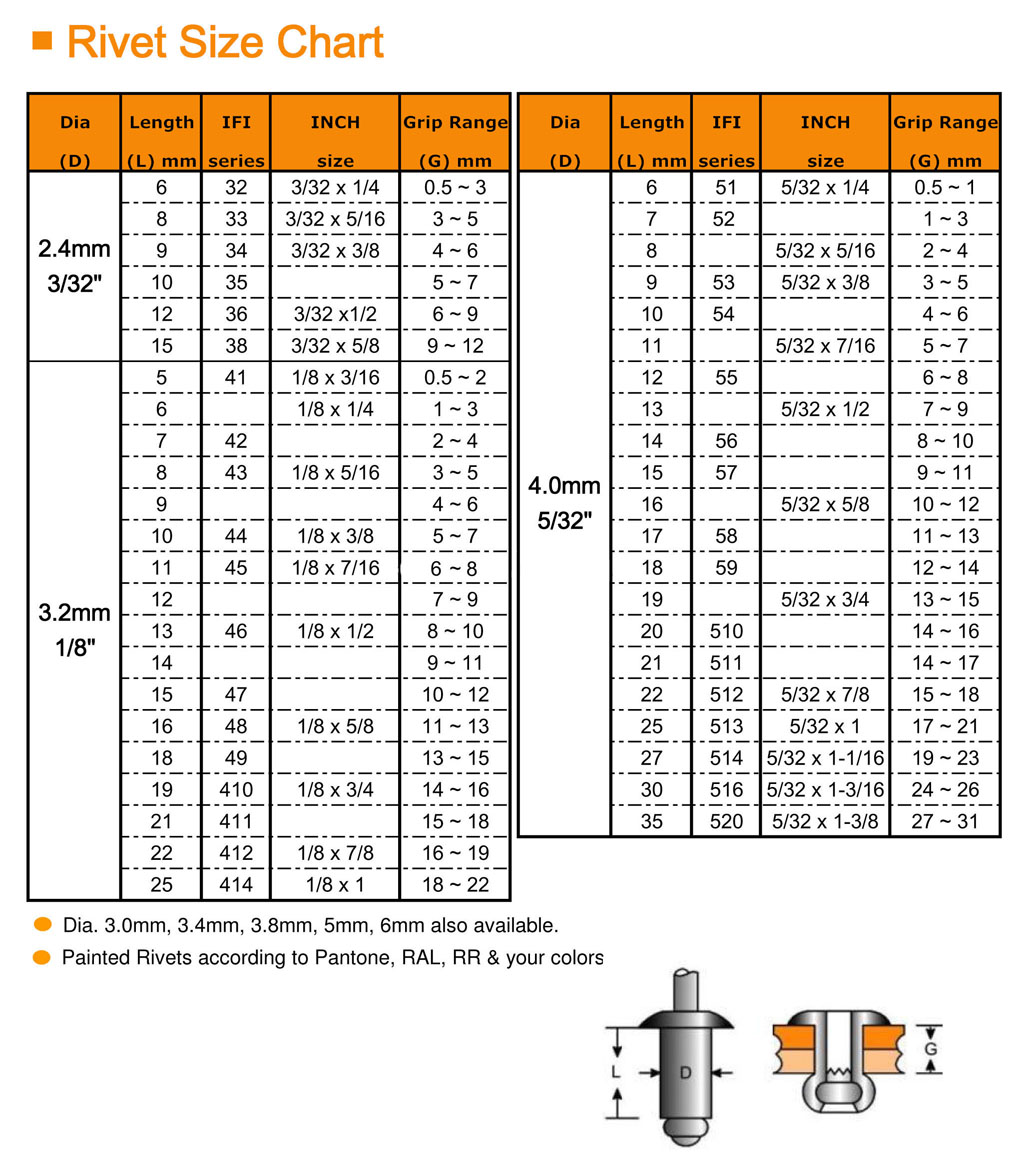

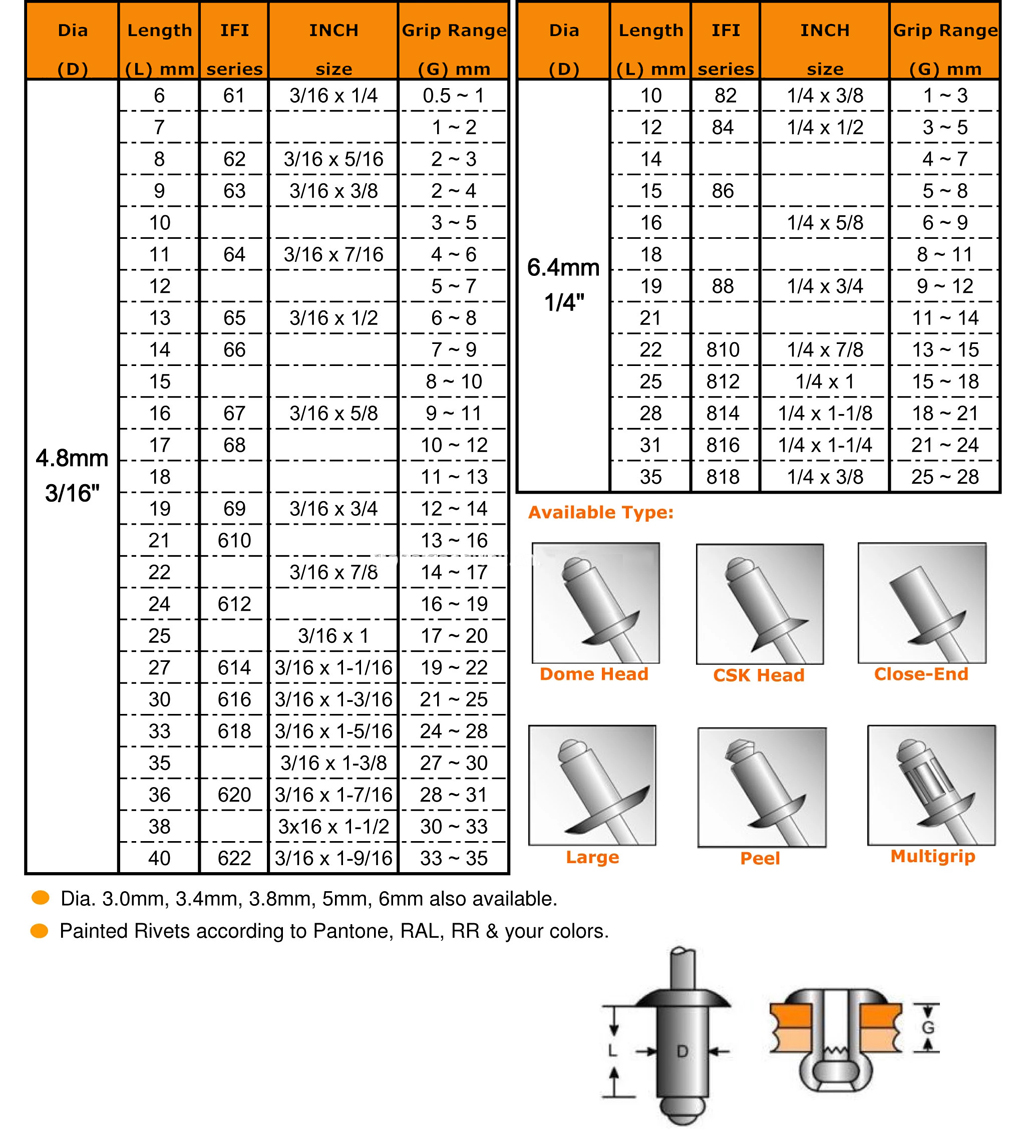

Aluminum pop rivets are also known as blind rivets , it is one of fasteners to rivet objects ,sizes normally from 2.4 to 6.4 for standard . Rivet is comprised of two components , a rivet body and mandrel , the rivet is first placed into an installation tool , and is then inserted into the application or vice versa , activating the tool pulls the rivets mandrel drawing the mandrel head into the blind end of the rivet body . This action forms an upset head on the rivet body and securely clamps the application materials together . The mandrel reahes its predetemined break load , with the spent portion of the mandrel breaking away and being removed from the set rivet , fast and easy to use blind rivet offer speed of assembly , consistent mechanical performance and excellent installed appearance , making blind riveting a relable and econmoical assembly method