Hot Sale Custom Concrete Screw Bolt In AnchorPopular

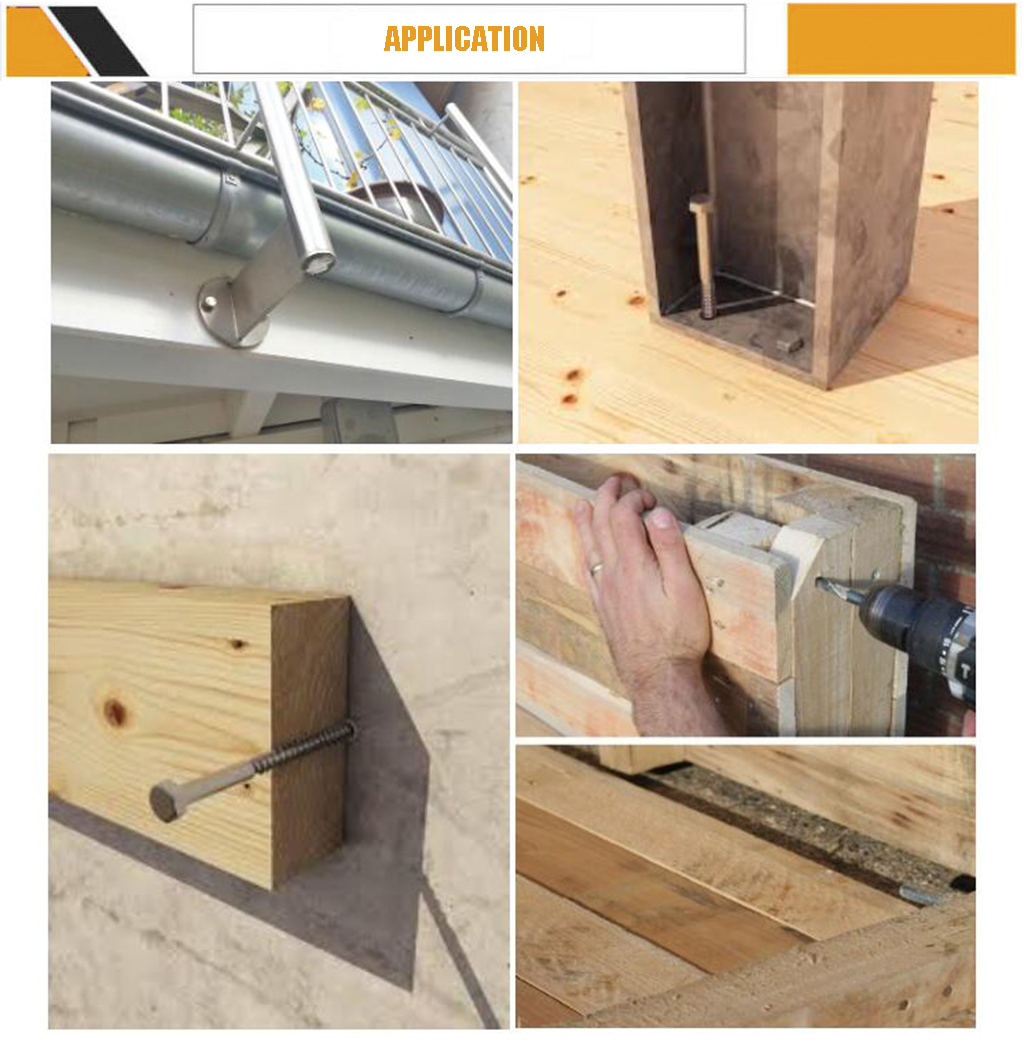

Coach screws are designed for metal to timber connections, or to join heavy timbers. Also known as lag bolts or lag screws, they have a square or hexagonal head engineered to be used with a wrench, spanner, or pliers. These screws come in a wide range of sizes, from the very small ones packed with furniture designed to be assembled by the consumer to extremely big ones used in large scale construction projects.

Wood screws are threaded fasteners that are used to join wooden workpieces. They aren’t necessarily made of wood. Rather, wood screws are available in many of the same metals and alloys as other screws. They are simply known as “wood screws” because they are designed for use with wooden workpieces.

We often export hex flange bolts around the world.We are always try our best to find a best solution for our customers together with the competitive price, the quality of goods and the the punctual delivery time.

We want to give customers the best service and quality assurance.We have strictly controlled quality to ensure provide high-quality products to every customer.The importance is that we delivery on time.Make customer satisfaction our greatest motivation, Welcome to visit our website and send us emails , inquiries and we will give you the response within 24 hours. Please feel free to do that, we will give you best service and offer you lower price.

|

Standard Specification |

|||

|

M6 |

M8 |

M10 |

M12 |

|

M6 x 30 |

M8 x 40 |

M10 x 40 |

M12 x 80 |

|

M6 x 40 |

M8 x 50 |

M10 x 50 |

M12 x 100 |

|

M6 x 50 |

M8 x 60 |

M10 x 60 |

M12 x 120 |

|

M6 x 60 |

M8 x 70 |

M10 x 70 |

M12 x 140 |

|

M6 x 70 |

M8 x 80 |

M10 x 80 |

M12 x 150 |

|

M6 x 80 |

M8 x 90 |

M10 x 90 |

M12 x 160 |

|

M6 x 90 |

M8 x 100 |

M10 x 100 |

M12 x 180 |

|

M6 x 100 |

M8 x 110 |

M10 x 120 |

M12 x 200 |

|

M6 x 110 |

M8 x 120 |

M10 x 130 |

M12 x 220 |

|

M6 x 120 |

M8 x 130 |

M10 x 140 |

M12 x 240 |

|

M6 x 130 |

M8 x 140 |

M10 x 150 |

M12 x 260 |

|

M6 x 140 |

M8 x 150 |

M10 x 160 |

M12 x 280 |

|

M6 x 150 |

M8 x 160 |

M10 x 180 |

M12 x 300 |

|

M8 x 170 |

M10 x 200 |

M12 x 350 |

|

|

M8 x 180 |

M10 x 220 |

M12 x 400 |

|

|

M8 x 190 |

M10 x 240 |

||

|

M8 x 200 |

M10 x 260 |

||

|

M10 x 280 |

|||

|

Standard Specification |

|||

|

1/4 |

5/16 |

3/8 |

1/2 |

|

1/4 x 1 |

5/16 x 1 |

3/8 x 1 |

1/2 x 2 |

|

1/4 x 1-1/4 |

5/16 x 1-1/4 |

3/8 x 1-1/2 |

1/2 x 2-1/2 |

|

1/4 x 1-1/2 |

5/16 x 1-1/2 |

3/8 x 2 |

1/2 x 3 |

|

1/4 x 2 |

5/16 x 2 |

3/8 x 2-1/2 |

1/2 x 4 |

|

1/4 x 2-1/2 |

5/16 x 2-1/2 |

3/8 x 3 |

1/2 x 5 |

|

1/4 x 3 |

5/16 x 3 |

3/8 x 4 |

1/2 x 6 |

|

1/4 x 4 |

5/16 x 4 |

3/8 x 5 |

1/2 x 7 |

|

1/4 x 5 |

5/16 x 5 |

3/8 x 6 |

1/2 x 8 |

|

1/4 x 6 |

5/16 x 6 |

3/8 x 8 |

1/2 x 10 |

|

5/16 x 8 |

3/8 x 10 |

||

|

5/16 x 10 |

|||

|

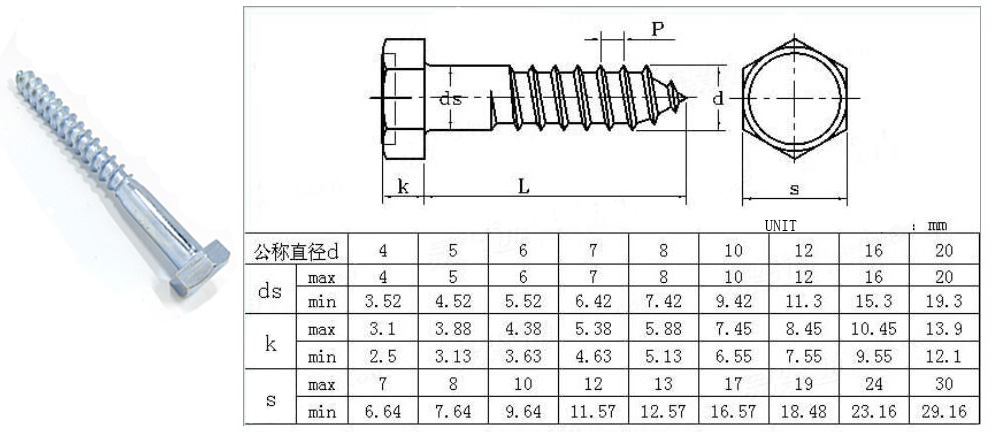

Installation Parameters |

||||

|

Thread |

Nut thickness |

Edge of a nut |

Drill hole |

Wrench Size |

|

M6 |

4 |

10 |

6mm |

10 |

|

M8 |

5.0-5.2 |

13 |

8mm |

13 |

|

M10 |

6.0-6.2 |

17 |

10mm |

17 |

|

M12 |

8.0-8.2 |

19 |

12mm |

19 |